BRICKMAKERS AND MASONS

The brickmaker was a key figure in the construction of the bastions in the fortress. It took precision and instinctive feeling to succeed in producing durable bricks. In Anders Jensen’s brick workshop a few kilometres northeast of the fortress, the clay was mixed with water and sand to the right consistency. When the stones were shaped and had dried in the drying rack, they would be fired in the kiln heated to exactly the right temperature. The fire in the furnace had to be kept going for several days while the bricks were fired. During the 1602–03 year of construction, Anders Jensen delivered over 80,000 bricks to the fortress construction. Of course, Anders did not work alone, but had many employees to shape, fire, stack and deliver the large quantities of bricks.

Once the bricks were delivered to the fortress, the masons took over. The master masons were among the highest paid craftsmen on the construction site. They worked intensively during spring, summer and autumn, but when it got too cold outside, the mortar did not solidify properly. Therefore, the masons’ work often stopped during the winter months.

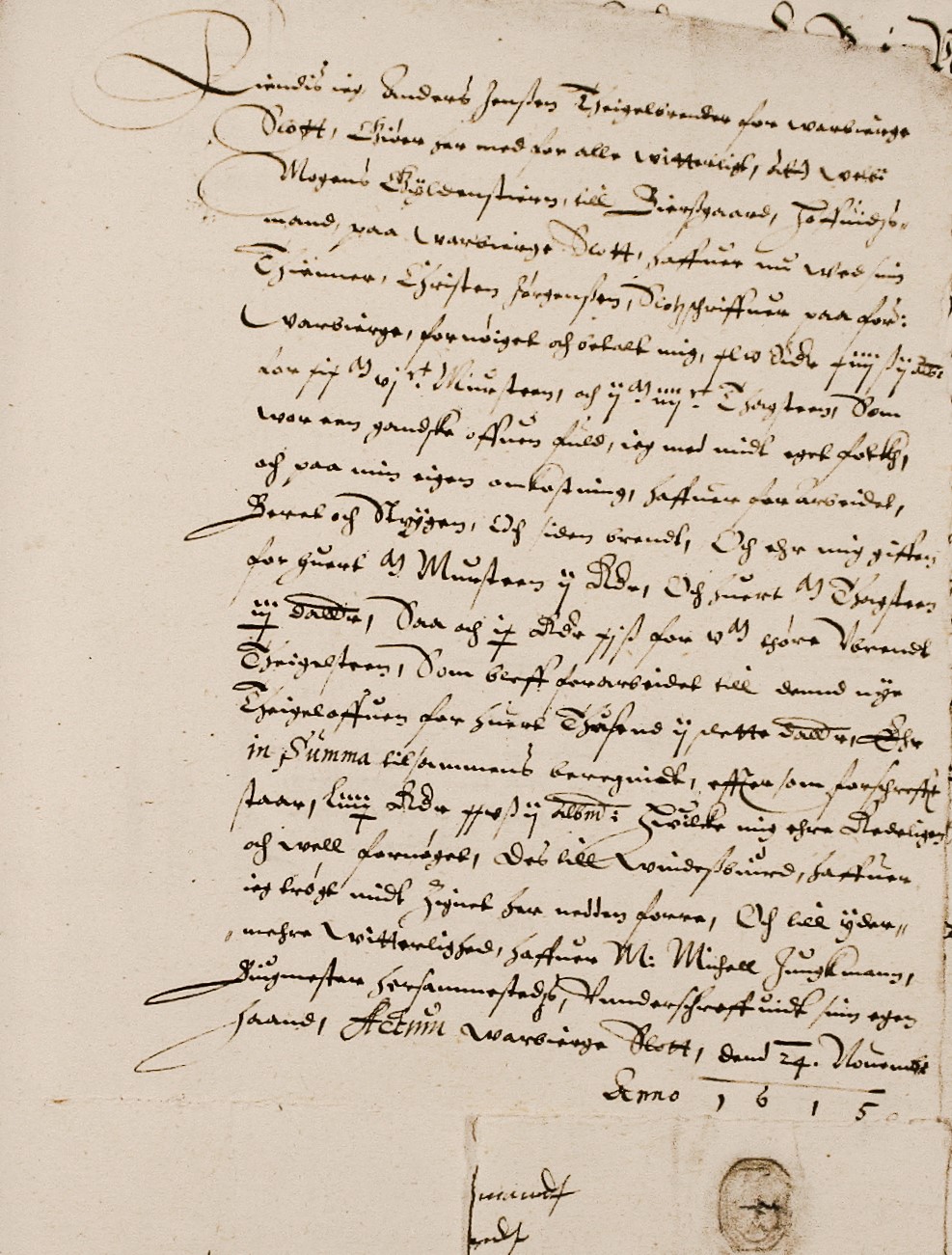

On this receipt from 24 November 1615, Anders the brickmaker has applied his seal at the bottom and in this way signed that he received payment for 19,600 wall bricks and 2,400 tile bricks “… which I with my own staff and at my own expense have produced, carried, formed and then fired”.

The original document is in the Danish National Archives in Copenhagen

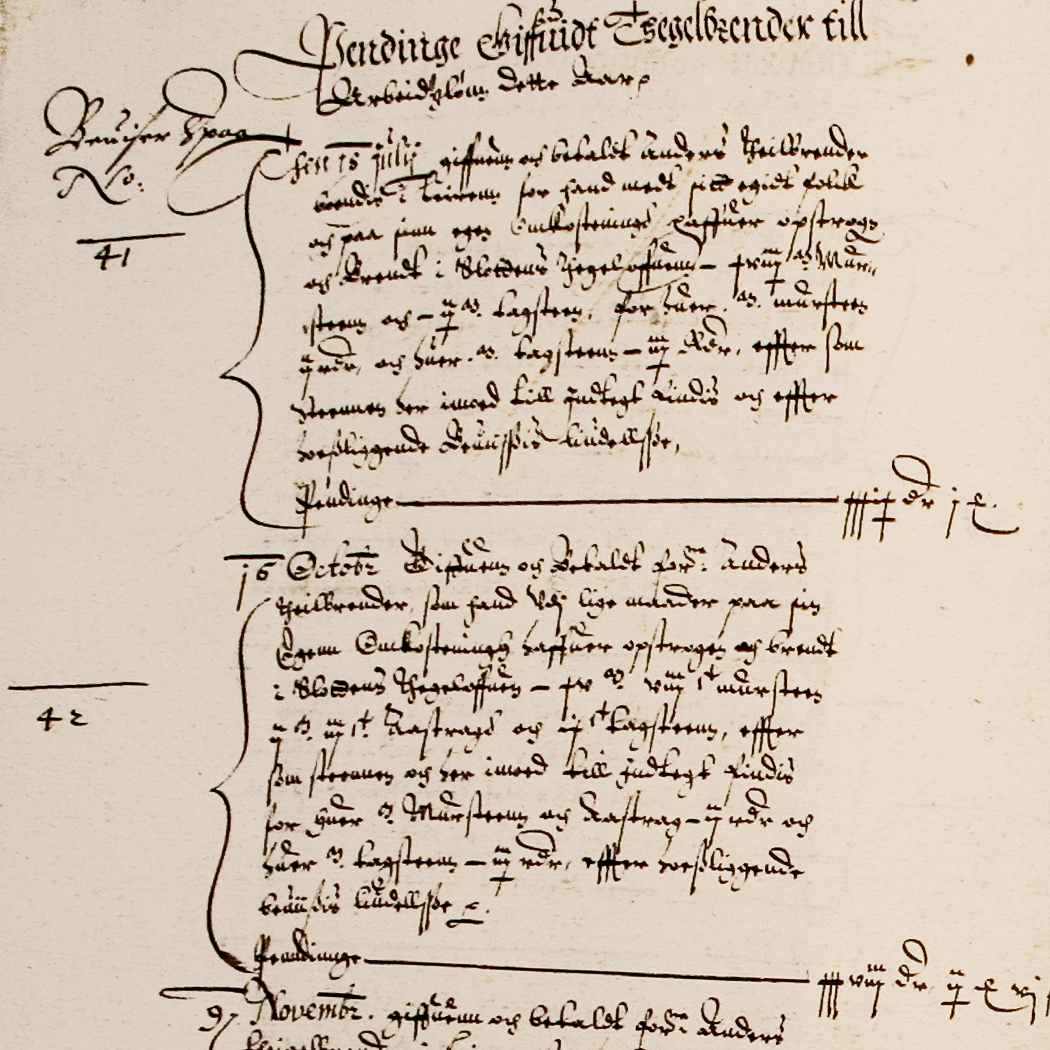

Two payments to the brickmaker from 18 July and 16 October 1616.

Masons at the fortress 1610–1611

During the 1610–11 financial year, 18 masons were employed in the construction:

A brickmaker could tell the quality of a fired brick by looking at its colour and by tapping on the stones to listen to the sound in them. A brickmaker would also spit on the brick to see if it was sufficiently fired enough. If the saliva was absorbed, the brick needed to be fired more. It or it could not be used outdoors as it would absorb moisture and perhaps be destroyed by the frost in winter. In the winter eller during the winter

Not only newly made bricks were used in the fortress construction. Lots of older bricks were retrieved from the disused medieval Ås Abbey, transported here on wagons and reused.